Standard door plastic powder has excellent mechanical properties

Source: FounderDate: June 29, 2024; Browse:0

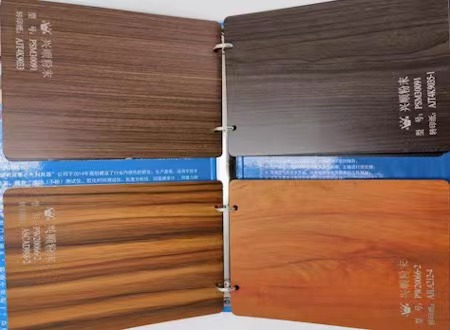

Don't underestimate the label door plastic powder. Although it is a small and invisible powder, it accumulates into a lot and can be well used on label doors. Its mechanical and heat resistance properties should not be underestimated, and its corrosiveness is relatively low. It is very suitable and has good sealing performance.

Plastic powder is a material used in the spray coating process. Simply put, plastic powder is heated at high temperatures and sprayed onto the surface of the material by compressed air.

Plastic powder and paint are two different processes. The spraying effect is good, the cost is low, the color is correct, and it is beautiful. Paint is expensive and the effect is average. Polyester paint or fluorocarbon paint can have better results. And doors and windows are generally used in environments with low corrosiveness, and the sealing performance of plastic is sufficient. Paint is used in environments with high corrosiveness. The final sprayed product coating is difficult to repair after being damaged, while paint is easier.

Plastic powder is a thermosetting powder coating used for electrostatic spraying.

Phenolic resin, also known as electric wood or electric wood powder. Originally colorless or yellow brown transparent material, it is often sold in the market with coloring agents to appear in colors such as red, yellow, black, green, brown, blue, etc., in the form of particles or powders. Resistant to weak acids and weak bases, decomposes when exposed to strong acids, and corrodes when exposed to strong bases. Insoluble in water, soluble in organic solvents such as acetone and alcohol. Phenol is condensed with formaldehyde. It includes: linear phenolic resin, thermosetting phenolic resin, and oil soluble phenolic resin. Mainly used for producing compression molding powder and laminated plastics; Manufacturing clear varnish or insulation, corrosion-resistant coatings; Manufacturing daily necessities and decorations; Manufacturing sound insulation, thermal insulation materials, etc. Common high-voltage electrical sockets, furniture plastic handles, and other phenolic resins, abbreviated as PF. Phenolic resin is a yellow, transparent, amorphous block like substance that appears slightly red due to the presence of free molecules. It has a specific gravity of 1.25-1.30 and is easily soluble in alcohol but insoluble in water. It is stable in water, weak acids, and weak bases. Resin made by condensation of phenol and formaldehyde under catalytic conditions, neutralization, and water washing. Due to the different catalysts used, they can be divided into two categories: thermosetting and thermoplastic. Phenolic resin has excellent acid resistance, mechanical properties, and heat resistance, and is widely used in industries such as anti-corrosion engineering, adhesives, flame retardant materials, and grinding wheel manufacturing. Phenol formaldehyde resin is the earliest industrialized synthetic resin.

Plastic powder and paint are different processes, which can have good effects, low cost, and relatively accurate colors. Compared to paint, which has a mediocre effect and is more expensive, plastic powder can be well applied in daily life and is a choice for many people.