How is plastic powder processed

Source: FounderDate: June 29, 2024; Browse:0

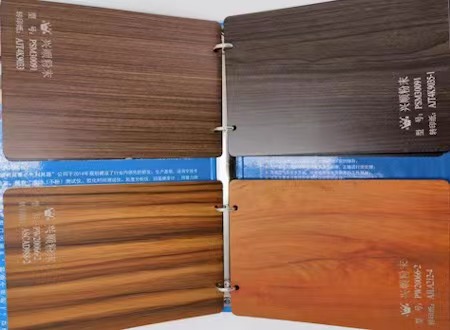

The cold winter is coming, and no matter what comfort and coolness it is, it is not the endorsement word of this season. It can warm the bed well, which is well reflected by its imitation solid wood plastic powder. With this plastic powder, whether it is door plastic powder or anything else, it can create a very good environment.

We have shape requirements for powder particles in different production processes. We usually refer to tear type powders as elongated or tadpole shaped, and their light transmission and reflection properties can lead to uneven color. Spraying on metal or other surfaces can cause unevenness and uneven adhesion after high-temperature baking.

The powder generated by impact can be described as stone shaped, with no significant difference between the longest and shortest ends. This type of powder particles can pass evenly through the nozzle, reducing blockage and achieving high atomization. The sprayed surface is uniform, but coarse powder particles can affect the uniformity of the sprayed surface, as well as the reflective and translucent properties, thereby affecting the appearance and adhesion.

By shaping the powder particles, we can obtain circular particles like yellow sand. This is achieved by grinding the water chestnuts in the shape of stones through shaping processes, or by melting the water chestnuts into the entire particle through temperature. This powder particle has first-class reflectivity, transparency, and uniformity. They are the future of plastic powder applications.

Particle size distribution

Particle size distribution generally refers to the distribution of powder size, and the narrower the distribution, the better the effect of plastic powder in subsequent production. On the contrary, the wider the distribution, the worse the effect

Now it is being processed very well, and the manufacturer is able to use their advanced equipment to produce products with high quality assurance. After molding, the plastic powder has a very good effect, the color is very correct, and the quality is very good.

- Previous article:Zhejiang standard door plastic powder saves more time and effort

- Next article:Powder coating saves resources and has high efficiency