What are the application scope of plastic powder?

Plastic powder is a new type of coating that saves a lot of cost compared to paint. It does not contain any harmful solvents and has almost zero volatile organic compounds compared to paint. It is easy to operate and can be said to be a more convenient coating than paint.

Plastic powder has a wide range of applications and is widely used in powder coatings and coating areas. It has excellent and strong adhesion, good flexibility and mechanical properties, high impact resistance, and good hardness. The spraying performance is also very good, which can efficiently achieve large-area spraying effect. As mentioned before, if the paint can achieve 1 volatility, our plastic powder can achieve 0 volatility, which is absolutely green and environmentally friendly. It does not contain various heavy metals and toxic and harmful gases, and has passed SGS certification testing. And it can also provide spraying services for various products, such as spraying for various facilities and furniture.

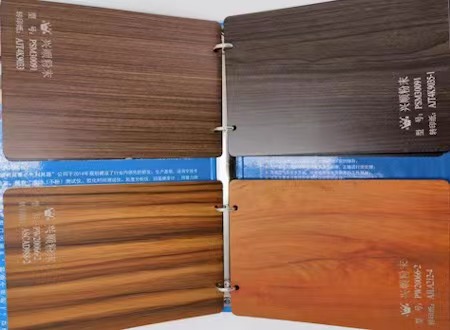

There is also a lot of room for color selection, with a rich sense of color and strong saturation.

As a powder coating that has emerged and ranked among the top in the construction and decoration industry in recent years

By using electric powder spraying equipment (electrostatic spraying machine), the powder is evenly sprayed onto the surface of the workpiece. Under the action of static electricity, the powder begins to adsorb evenly and form a powdery coating on the surface of the workpiece. After high-temperature baking and solidification, the final coating with different effects is completed. Overall, the spraying process has far surpassed the old-fashioned spraying process, both in terms of environmental friendliness, operation, and cost. Moreover, after a long period of use, there will be problems such as paint peeling and fading. Compared with the old-fashioned paint spraying process, the plastic powder spraying process has a longer service life and will not experience fading or aging.

This article tags:

- Previous article:Do you know what kind of material plastic powder is?

- Next article:What kind of material is plastic powder