The plastic powder process is indispensable, and Xingshun New Materials reminds you to pay attention!

There are actually many names for plastic powder, mainly referring to transparent materials in yellow brown color. Over the years, the export volume of plastic powder has been very large. After development, many people who want to engage in the plastic powder industry first need to understand the plastic powder process. If you are interested, let's learn more about it together.

Pre treatment process of plastic powder: degreasing, rust removal, phosphating, passivation. After processing the workpiece, not only is there no oil, rust, or dust on the surface, but a uniform, rough, and rust free gray phosphating film is also produced on the silver white glossy surface to improve the adhesion of the spray coating without rusting. Related equipment and raw materials: pre-treatment tank (concrete tank or plastic welding tank); Related chemical drugs: sulfuric acid, hydrochloric acid, soda ash (Na2CO3), acidic demulsifier, phosphating solution, passivation solution.

2. Plastic powder electrostatic spraying process: Electrostatic powder spraying: Using the principle of electrostatic adsorption, a layer of plastic powder is evenly sprayed onto the surface of the workpiece. The fallen plastic powder can be recycled through a recycling system, sieved, and reused. Relevant equipment and raw materials: 1 electrostatic spray (electrostatic powder spray) more than 1 spray with powder recovery function (single or double bit); Plastic powder (also called spray raw material of powder coating).

3. High temperature curing process of plastic powder: Push the sprayed workpiece into the curing furnace, heat it to the predetermined temperature (usually 185C), and hold it for an appropriate time (15 minutes). Turn on the stove, take out the cooling, and you can get the finished product. Related equipment and raw materials: hardening furnace (parameters requiring automatic control: temperature, insulation time). Heating methods for hardening furnaces: electric heating, fuel heating, or gas heating.

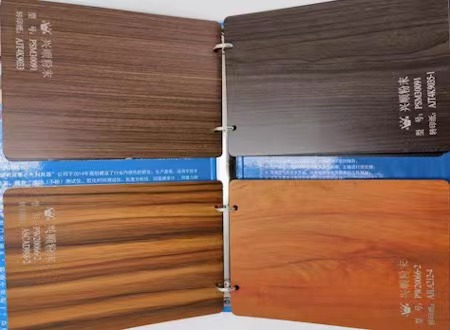

4. Plastic powder electrostatic powder decoration process: The treatment process adopted by electrostatic spraying workpieces to achieve various wood grain and other appearance effects (other plastic powders can be selected for execution).

The above is the relevant introduction about the plastic powder process, hoping to help everyone! In recent years, the main reasons for the obstruction of China's paint product exports are the lack of product innovation, unclear brand market positioning, and labor market shortages, which have constrained the export of China's paint products.