What is the processing flow of plastic powder spraying

The principle of electrostatic powder spraying technology utilizes the phenomenon of corona discharge to adsorb powder coating onto the workpiece. Powder coating is supplied by the powder supply system through compressed air gas into the spray gun. The high voltage generated by the high-voltage electrostatic generator is added to the front end of the spray gun. Due to corona discharge, dense charges are generated nearby. The powder is sprayed from the nozzle, forming charged coating particles. Under the action of static electricity, they are sucked into the opposite workpiece. As the powder increases, the charge accumulates more. When it reaches a certain thickness, due to electrostatic repulsion, it no longer adsorbs, allowing the entire workpiece to obtain a certain thickness of powder coating. Then, it is melted, leveled, and solidified by heat, forming a hard film on the surface of the workpiece.

Electrostatic spraying process flow:

Workpiece degreasing → water washing → water washing → passivation treatment → drying → spraying → drying

Advantages of electrostatic spraying:

1. No thinner, construction is harmless to the environment and non-toxic to human health;

2. The coating has excellent appearance quality, strong adhesion and mechanical strength;

3. Short curing time for spray coating construction;

4. The corrosion resistance and wear resistance of the coating are much higher;

5. No primer;

6. Simple construction with low technical requirements for workers;

7. Cost lower than spray painting process;

8. During the spraying process, there will be no flow phenomenon commonly seen in electrostatic powder spraying.

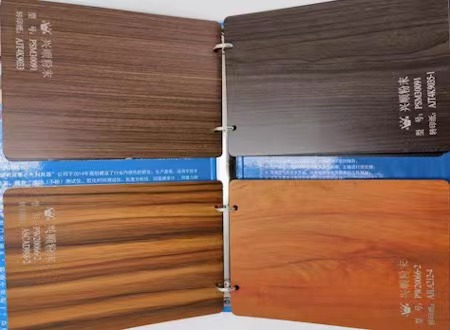

Spray coating is commonly referred to as electrostatic powder coating. It uses an electrostatic generator to charge plastic powder, adsorb it onto the surface of an iron plate, and then bake it at 180-220 ℃ to melt the powder and attach it to the metal surface. Spray painted products are mostly used for indoor enclosures, and the paint film presents a smooth or matte effect. Spray powder mainly includes acrylic powder, polyester powder, etc.

- Previous article:What types of plastic powder can be divided into

- Next article:What are the advantages of plastic powder materials?