What is the difference between plastic powder used indoors and outdoors?

Plastic powder is an additive widely used in plastic processing and manufacturing, with multiple functions. They can improve the efficiency and quality of plastic processing, regulate the physical and mechanical properties of plastics, and enhance the adhesion of plastic coatings. The application of plastic powder varies in different fields, but it generally has the function of improving product quality, increasing production efficiency, and reducing costs. Outdoor plastic powder and indoor plastic powder are multi-layer plastic coatings mainly used for surface coatings of metal materials, plastic materials, etc. Through electrostatic spraying construction, the material surface is uniformly covered, and then baked and cured at high temperature to form a tough plastic coating.

The difference between outdoor plastic powder and indoor plastic powder

1. Performance differences

Outdoor plastic powder needs to have stronger anti-aging and weather resistance, because the coating is easily damaged by weather factors such as wind, rain and snow in outdoor environment. Therefore, outdoor plastic powder requires materials with higher weather resistance, corrosion resistance, and UV resistance.

Indoor plastic powder pays more attention to its anti-corrosion, anti-oxidation, and anti yellowing effects, as there are generally fewer corrosive factors in indoor environments. Meanwhile, indoor plastic powder can reduce color requirements. For example, in the commercial building industry, it is recommended to use indoor plastic powder for indoor lightbox coating.

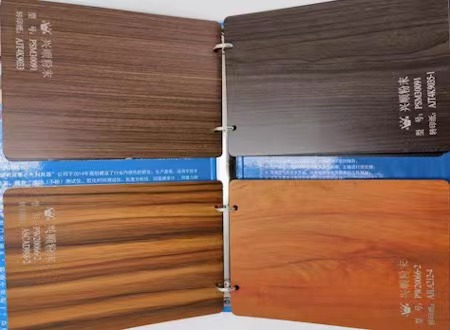

2. Appearance differences

Outdoor plastic in pink is more full and bright, with stronger coverage. Due to strong lighting in outdoor environments, colors should be brighter for display in sunlight. Therefore, outdoor plastic powder can also be colored according to actual needs.

Indoor plastic with pink color has strong stability and is not affected by factors such as oxidation, ultraviolet radiation, and temperature changes. Therefore, indoor plastic has a relatively uniform pink color and is less prone to fading, yellowing, and other phenomena. This also provides designers with more color selection space.

Through the analysis of outdoor plastic powder and indoor plastic powder, we can see that there are differences in their performance and appearance. Simply put, outdoor plastic powder is more weather resistant, aging resistant, and more suitable for outdoor environments; Indoor plastic powder is better in terms of corrosion resistance, ultraviolet radiation, and oxidation, making it suitable for indoor use. In short, if you want to purchase suitable plastic powder coatings, you need to choose according to your actual needs. Meanwhile, it is recommended that consumers fully understand relevant knowledge before purchasing and choose manufacturers with good reputation.

- Previous article:What are the uses of plastic powder that the material company told you?

- Next article:How to remedy scratches caused by spray powder?